MCR

Collaborative robots are mainly used for material handling between conveyor lines. It is equipped with different carriers such as totes and trays to achieve intelligent flow production between warehousing, conveyor lines, and machines.

Product Features

Lifting function

Loading and unloading materials between all lines within a height range of 280 mm to 1,100 mm

Flexible and dynamic

Turning diameter φ 1,200 mm, low requirements for ground and aisle width

High security

360° horizontal obstacle avoidance, scalable for ToF camera to obtain 3D obstacle avoidance

High-accuracy Positioning

Overhead 360° laser navigation, strong anti-interference

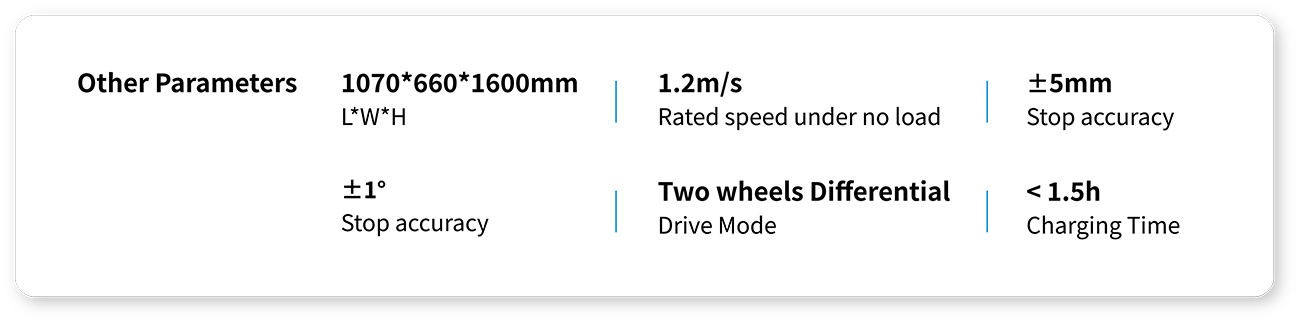

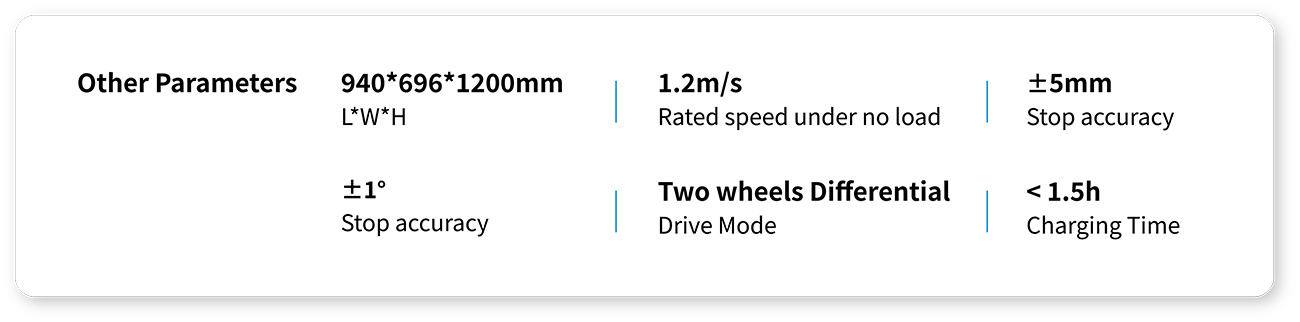

CR Series

height from the ground: 280~1100mm

Docking height

Load Capacity

Navigation Mode

Climbing Ability

Rated Operating Time

Docking height

Load Capacity

Navigation Mode

Climbing Ability

Tote Dimensions

Rated Operating Time

Industries

Smart navigation, high accuracy, high efficiency, applicable to various logistics, ensure safety and accuracy in business.

X series robots play an important role in e-commerce warehousing. They accurately locate and transport goods through autonomous navigation technology, significantly improving warehousing efficiency, reducing labor costs, ensuring warehousing safety, realizing intelligent and visualized warehousing management, and providing strong support for the rapid development of the warehousing e-commerce industry.

In the automotive parts industry, X series robots with their efficient and accurate handling capabilities, effectively improve the storage and distribution efficiency of parts, reduce labor costs, and ensure the continuity and safety of the production line, providing important technical support for intelligent manufacturing and lean production in the automotive parts industry.

The application of X series robots in the consumer electronics industry has achieved efficient handling and storage of electronic components and finished products through its high-precision navigation and positioning technology, significantly improving warehouse operation efficiency, reducing labor costs, and providing strong support for the rapid response to market changes and high-quality development.

With its efficient and hygienic handling characteristics, X series robots ensure the rapid circulation of raw materials, semi-finished products, and finished products in warehouses and production lines, while meeting the industry's high standards for cleanliness and safety, laying a solid foundation for quality control and production efficiency improvement of the food and pharmaceutical industry.